Knotting Machines From Jaytex

(We are the ONLY agents of Jaytex)

Warp Tying (Beam Knotting) Machine

Production of fabrics successively with the same design is easier utilizing a warp-tying machine to exchange the beams. Jaytex warp tying machine is the most effective and low budget and maintenance free machine which fulfills this requirement to a large degree. Tying installations, which requires a minimum of time for changing the warp contributes a lot to the efficiencies and low stoppage rates of the high performance looms. Jaytex is the pioneer in developing warp tying equipment with 100% Indigenous components. End to end warp tying at a high speed, directly on loom along with healds, reeds etc.

It is a highly compact & sophisticated machine, which deals with delicate yarn at a very high speed. The working range of this machine is practically unlimited it can tie any material with or without lease may it be cotton, spun, worsted, filament, P.V., woolen, denim slub, furnishing auto or industrial fabric from finest to coarsest with high efficiency at low labour cost. Easy adaptability to different tying methods at any time. Maintenance free timing belt drive in all the machines. It is a guarantee for service, spares & economy.

JAYTEX fully automatic warp tying machine. Fitted with maintenance free timing pully belt drive, having 24 – volts permanent magnet D.C. electric motor 3000 R.P.M., with cooling fan. For speed control P.C.B. with control pot and on-off switch is provided. Completely adjustable light fitting for bright illumination on the knotting spot. The machine is totally enclosed with necessary cover from all the sides, to prevent fiber, dust, lint, yarn residuals etc. entering the working parts. Digital counting & auto stop motion in case of double end selection or breakage optional available in all model machines.

Models for Warp Tying (Beam Knotting) Machine

JS Model

Tying from both sheet to sheet for sized warps, selection by selector needles, count range 6’ s to 80’s single.

JL Model

For leased warps. Tying from both lease to lease, for the warps wound on sectional warping or leased by machine after sizing with double lease. Count/ Din. Range 110’s cotton / 50 Din. Filament up to 6’s cotton 2000 Din. Any type of mixed blends, worsted, spun, P.V. etc.

JSL Model

Universal type provided with lease to lease & sheet to sheet tying module. Yarn range as above.

P.U.A.C. Model

Ideally developed for suiting, shirting, furnishing SLUB & FANCY yarn. With technical provisions adapted any counts and type of yarn with un-even condition provided in a single width, can be knotted with or without lease (two selection system). As per the thickness or count of warp the automatic self-adjusting thread clip assures appropriate tension to the threads of both layers no matter how coarse or fine they are. With variable speed control inching motion brighter tube illumination for clear knotting vision the PUAC is developed for today’s high-speed textile industry.

Pattern Control Model

A uniquely developed machine with multiple selection system (i.e. L to L, S to S, L to S, S to L) can be used as per your knotting needs. The automatic self adjusting thread clip takes care of any type of pattern with a multiple selection system, & double end knock-off arrangement. It also takes care of different series of yarn with un-even counts and denier wound in one single width. Jaytex machines are electronically regulated it can infinitely adjust from 60 to 600 knots per minute according to count and condition of the warp. An emergency stop motion in case of a fault in selection. Clear display of pattern counts and so on in progressive counting. The machine can handle virtually any yarn delicately without any worry or damage, be it multi filament, pure silk, double or single thread with multi colored pattern, and variations in yarn count with or without lease. Ranging from the finest to coarsest. Ideally suitable for suiting, shirting and furnishing SLUB & FANCY yarn.

Heavy Duty Model

For very heavy counts and Din. sheet to sheet or lease to lease ranging from single 6’s up to 4 X 6’s and 3000 Din. higher range then single 6’s or

800 Din. “PUAC” model machine is recommended.

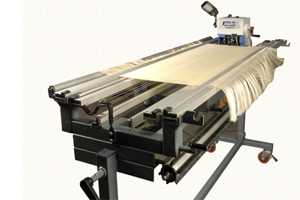

Yarn Dressing Frame

Jaytex frames are manufactured as per your requirement in height & width ranging between 120 cms. (50”) up to 400 cms. (160” ) With in this range every requested width can be accommodated in stages of 25 cms. (10”). For twin beams your choice are either one frame covering both the warp beam width, or one single frame with double side clamping system or two single frame with coupling device. Double width, separable warp tying frame permit rationalized working on looms with twin warps. The separated tying frame can also be used for looms of normal single beams.

Jaytex dressing frames are made out of specially extruded alloy sections which are very sturdy and light weight and at the same time durable for years of service. The yarn clamp holding and tensioning device are simplified for faster dressing; it is designed for easy adjustments vertically and horizontally, to adjust the height according to your loom. They come in very wide range of working width, according to your looms and choice.

For faster dressing and easy clamping of coarser warps below 12’s we recommend you our HD/UB type frames, provided with very sturdy U type rubberized, alloy clamps, with oval shaped EN-9 steel bars. Clamping system of Jaytex dressing frame is designed to press the entire warp sheet in parallel and firm condition. Rubbers on both the sides of tension rails guarantees firm grip to the most slippery and fine warp. Jaytex also has Heavy Duty Bar Tensioning Yarn Dressing Frame specially developed for denim & coarser warps. These frames are very sturdy. Special type frames for any imported machines can also be made on order.

|

|

|

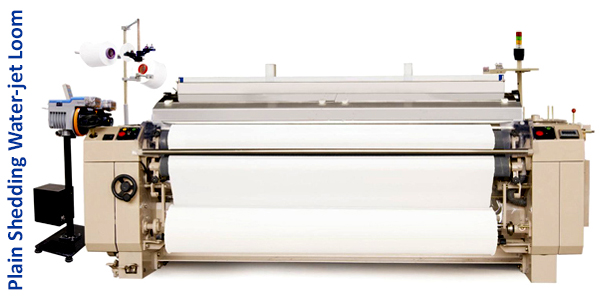

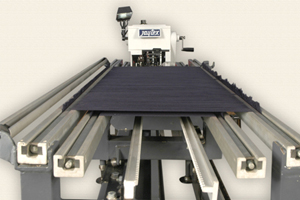

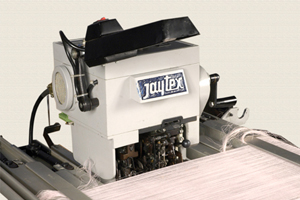

Warp Tying Knotting Machine 01 |

Warp Tying Knotting Machine 02 |

|

|

|

|

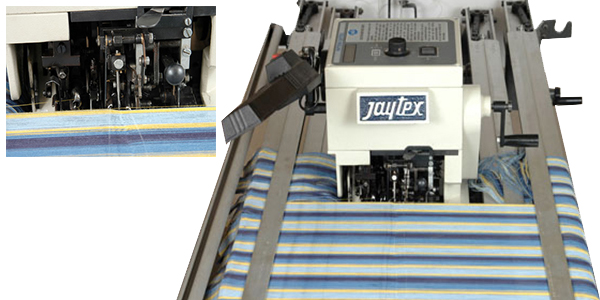

Warp Tying Knotting Machine 03 |

Warp Tying Knotting Machine 04 |

|

|

|

|

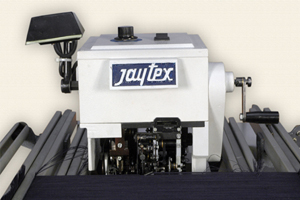

Warp Tying Knotting Machine 05 |

Warp Tying Knotting Machine 06 |

|

|

|

|

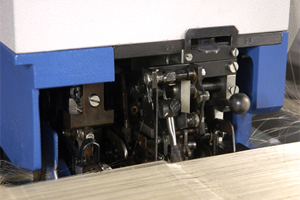

Warp Tying Knotting Machine 07 |

Warp Tying Knotting Machine 08 |

|

|

|

|

Warp Tying Knotting Machine 09 |

Warp Tying Knotting Machine 10 |

|

|

||

Warp Tying Machine Maintenance |

We also supply all types of spare parts for Warp Tying Machine on advance order.